-

Drying Oven Series

The Dengsheng Instrument drying oven boasts a wide operating temperature range, from 250℃ to 600View More

-

Vacuum Box Series

Vacuum drying ovens represent a significant advancement and leap forward in heat treatment technologView More

-

Explosion-proof Series

Explosion-proof instruments and equipment are essential products for modern industrial safety systemView More

-

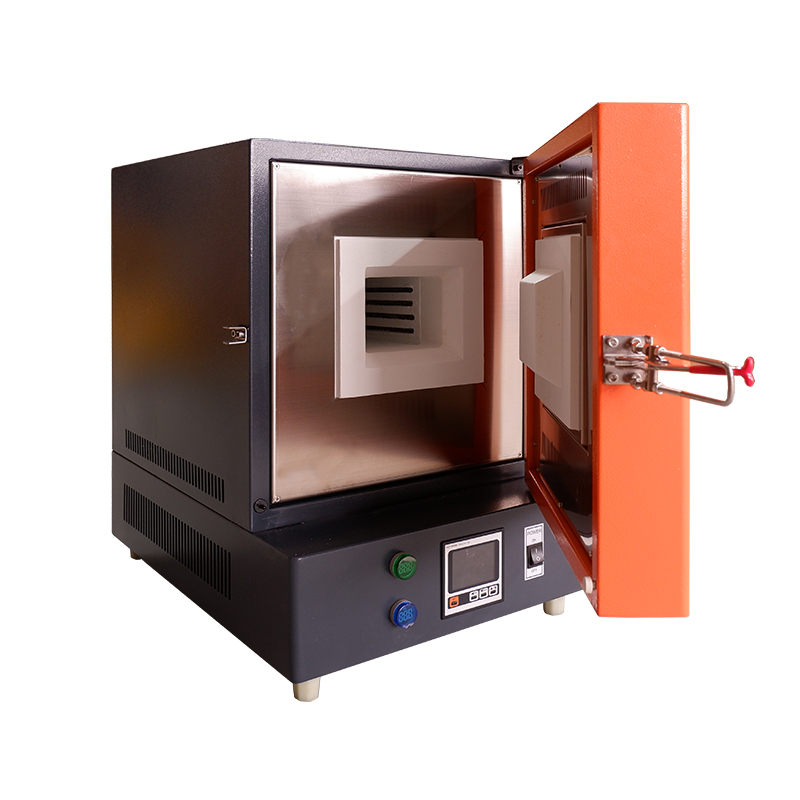

High-temperature Furnace Series

In modern scientific research and high-end manufacturing, box-type resistance furnaces, ceramic fibeView More

-

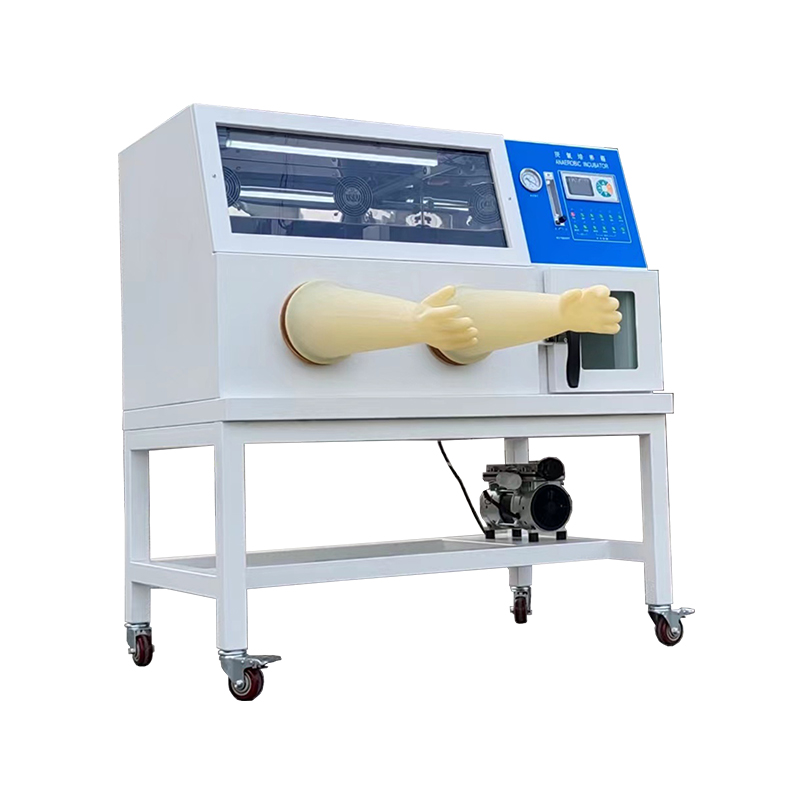

Incubator Series

Incubators are core equipment in modern life science and biotechnology research. By simulating and mView More

-

Test Chamber Series

Test chambers are core simulation and verification equipment in modern industrial and scientific resView More

-

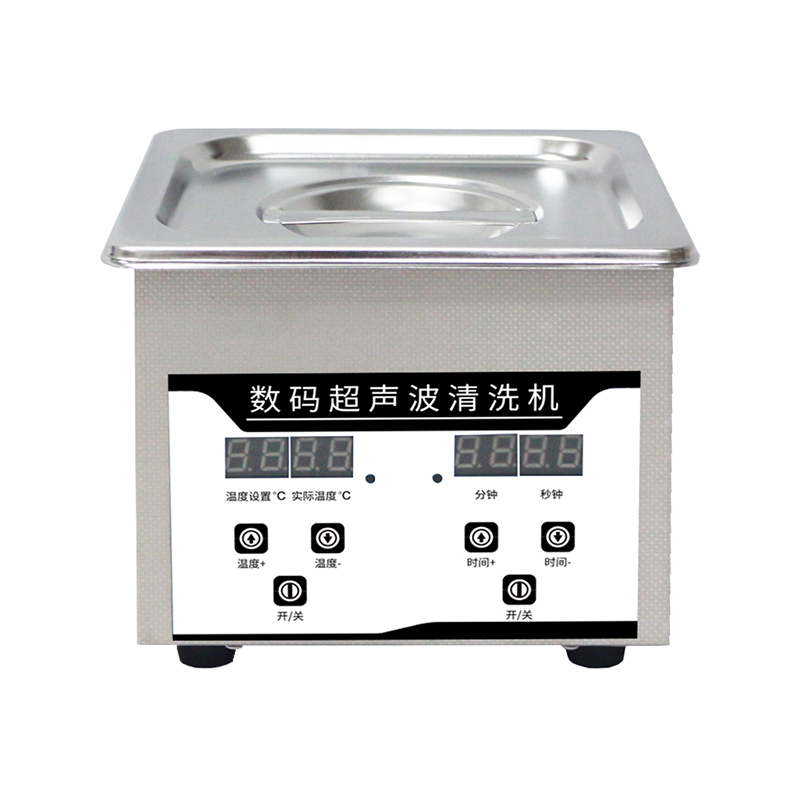

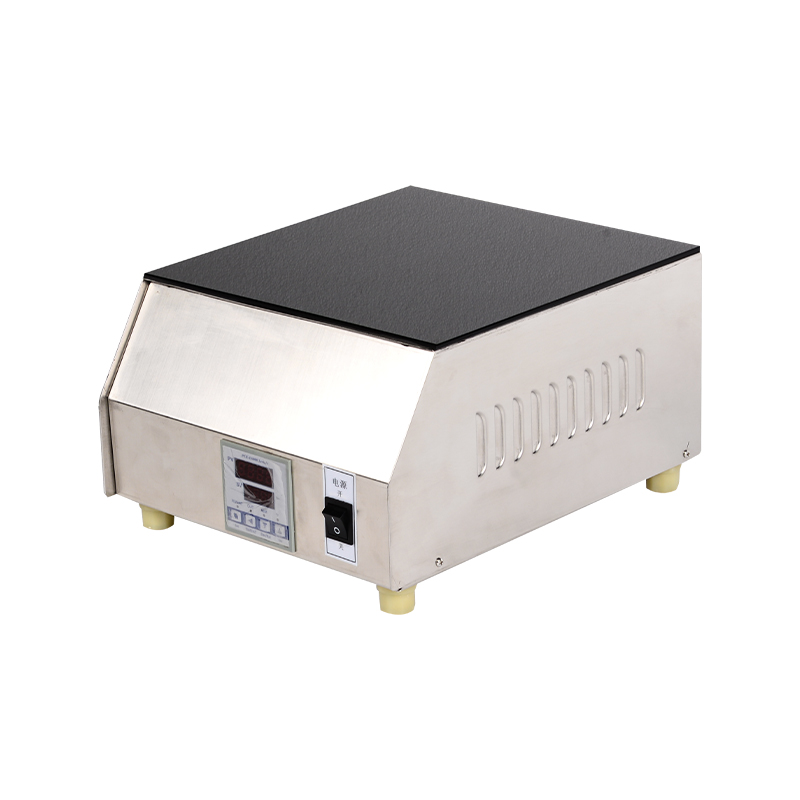

Other Series

The Other Series offers a comprehensive range of precision laboratory and industrial equipment desigView More

About Dengsheng

Laboratory Equipment Solution

Shanghai Dengsheng Instrument Manufacturing Co., Ltd. is a high-tech enterprise integrating R&D, production, sales, and service. We specialize in the manufacture of high-end laboratory equipment, including ovens, incubators, industrial furnaces, and environmental test chambers.Laboratory Equipment Factory and Laboratory Equipment Company in China.

We boast an 8,000-square-meter modern production facility, a dedicated R&D team, 23 national patents, and ISO-9001 quality management system certification. Our solutions are widely used in cutting-edge fields such as aerospace, semiconductors, biomedicine, automotive, and new materials. We have established in-depth partnerships with top universities and industry leaders, and our products are exported to many countries and regions around the world.

Adhering to the principles of "Integrity, Innovation, and Win-Win," we are committed to becoming your trusted partner with reliable quality and dedicated service. ---Laboratory Equipment Solution.

- Extensive experience in custom equipment.

- 1000+ successfully executed projects.

- Excellent product quality and thoughtful customer service.

We welcome inquiries and cooperation from both new and existing customers, providing professional equipment solutions.

Español

Español  عربى

عربى