[ Our Solutions ]

Industries We

Serve

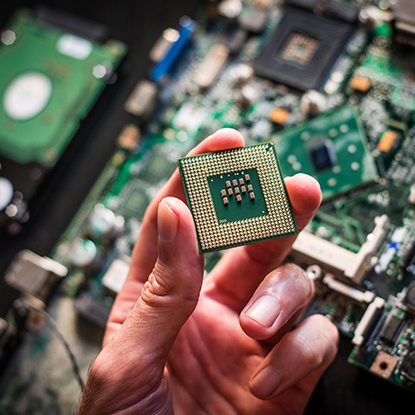

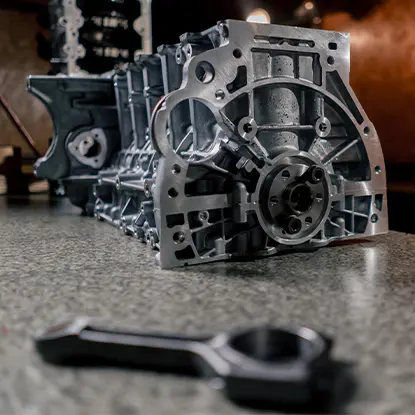

Products widely used in multiple important industry fields, becoming powerful assistants for improving product quality.

Our

Categories

Categories

Complete series of laboratory equipment meeting precise experimental needs across different industries

[ Who We Are ]

About Dengsheng Instruments Professional Laboratory Equipment

Manufacturer

Shanghai Dengsheng Instrument Manufacturing Co., Ltd

is a high-tech enterprise integrating R&D, production, sales, and service. We specialize in the manufacture of high-end laboratory equipment, including ovens, incubators, industrial furnaces, and environmental test chambers.We boast an 8,000-square-meter modern production facility, a dedicated R&D team, 23 national patents, and ISO-9001 quality management system certification. Our solutions are widely used in cutting-edge fields such as aerospace, semiconductors, biomedicine, automotive, and new materials. We have established in-depth partnerships with top universities and industry leaders, and our products are exported to many countries and regions around the world.

-

0+Factory Area

-

0People

-

0+Cooperating Customers

-

0+Patent

[ Our Strength ]

High-Tech Enterprise, Reliable Lab Equipment Partner

With a modern production base of over 8,000 sqm, a dedicated R&D team, and 23 national patents, Shanghai Dengsheng Instruments is committed to providing high-performance laboratory equipment and environmental testing solutions, from standard to custom. We drive innovation, build on

quality, and serve global scientific research and industrial fields.

-

Collaboration & Global Vision

Collaboration & Global Vision -

Products & Applications

Products & Applications -

Manufacturing & Quality

Manufacturing & Quality -

R&D & Innovation

R&D & Innovation

[ Our Blogs ]

Explore Our

Latest Post