2025/11/27

2025/11/27

With a deep commitment to the global market, Shanghai Dengsheng Instruments has earned international acclaim for its quality.

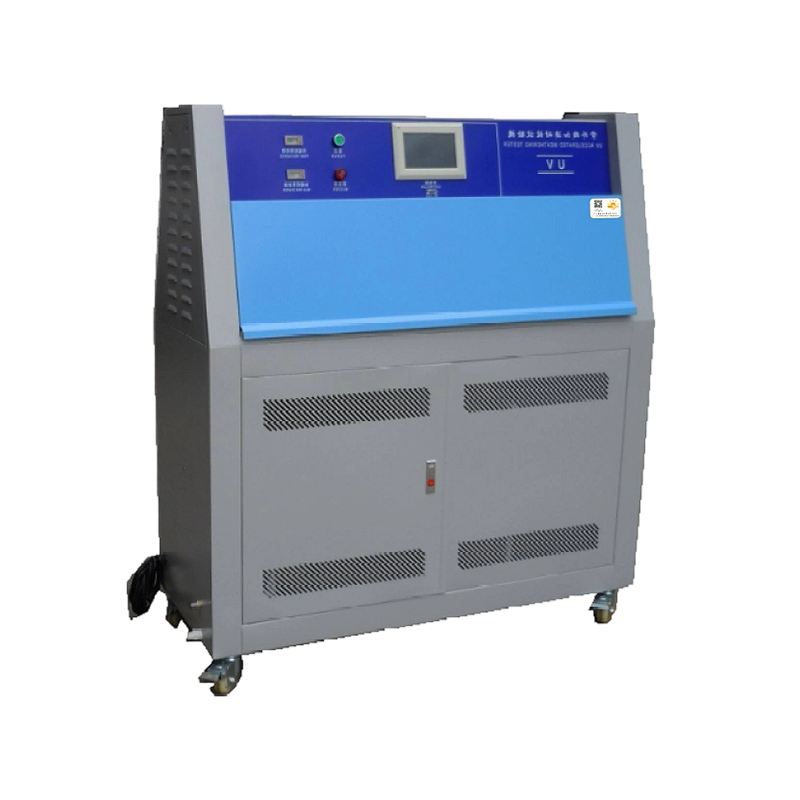

This UV accelerated ageing test chamber employs imported UVA-340 fluorescent ultraviolet lamps as its light source, simulating damage caused by sunlight, rainwater and dew. The UV weathering chamber utilises fluorescent ultraviolet lamps to replicate the effects of solar radiation, while employing condensed moisture to simulate dew. Test materials are subjected to alternating cycles of light exposure and humidity at specified temperatures. This accelerated weathering testing yields results regarding material resistance to environmental degradation. Within days or weeks, the UV chamber replicates damage typically occurring outdoors over months or years. Types of damage include: fading, discolouration, loss of gloss, chalking, cracking, clouding, blistering, embrittlement, strength reduction, deterioration, and oxidation. This unit incorporates a spray device.

This UV accelerated ageing test chamber simulates environmental conditions found in natural climates, including ultraviolet radiation, rain exposure, high temperatures, high humidity, condensation, and darkness. By reproducing these conditions and combining them into a cycle, the chamber automatically executes the specified number of cycles. This constitutes the operational principle of the UV ageing test chamber. Throughout this process, the equipment automatically monitors black panel temperature and water bath temperature. By configuring an irradiance measurement and control device (optional), light irradiance can be measured and regulated, maintaining it at 0.76 W/m² at 340 nm or a specified set value, thereby significantly extending lamp service life.

Light Source

1. The light source employs eight imported ultraviolet fluorescent lamps, each rated at 40W. These ultraviolet fluorescent tubes are distributed across both sides of the machine, with four tubes on each side. Users may select either UVA-340 or UVB-313 light sources for configuration;

2. The spectral energy of UVA-340 tubes is primarily concentrated at 340nm wavelength, while UVB-313 tubes concentrate around 313nm;

3. This apparatus employs UVA-340 tubes;

4. As fluorescent lamp energy output gradually diminishes over time, to minimise the impact of light energy decay on testing, this chamber replaces one old lamp with a new one every quarter of the total lamp lifespan across all eight lamps. This ensures the ultraviolet light source is always composed of both new and old lamps, thereby maintaining a constant light energy output;

5. Effective lamp lifespan is approximately 1600 hours;

6. Equipped with a true-colour touchscreen PID temperature intelligent controller, offering high precision and excellent stability;

Electrical Control

1. Black panel temperature and condensation temperature are both controlled via the controller;

2. Primarily utilises imported electronic components; irradiance uniformity: ≤4% (at the sample surface);

3. Black plate temperature monitoring: Utilises standard Pt-100 black plate temperature sensors to precisely regulate sample surface temperature throughout testing;

4. Black plate temperature setting range: BPT 40-75°C;

5. Temperature protection device threshold: Maximum limit of 93°C ±10%;

6. Black plate temperature control accuracy: ±0.5°C;

7. Water Tank Temperature Monitoring: During the cyclic test, a test phase involves dark condensation where the chamber must generate saturated water vapour at elevated temperatures. When this vapour encounters the relatively cooler specimen surface, condensation forms dew droplets;

8. Water Tank Positioned at Chamber Base with Built-in Electric Heater;

9. Water Tank Temperature Control Range: 40–60°C;

10. The test chamber is equipped with a time controller, range 0–530 hours, with power failure memory function;

Standard Specimen Clamps

1. Supplied with several standard specimen clamps (75×150 mm or 75×290 mm, thickness 1–15 mm);

2. Non-standard dimensions must be specified by the user at the time of ordering;

3. Samples may be loaded directly without the use of sample holders or racks;

4. Standard sample holders feature 14 rows per surface, with one rear row designated for mounting a blackboard thermometer;

Chamber Construction Materials

1. Inner chamber constructed entirely from SUS304 stainless steel plate;

2. Outer casing manufactured from SUS304 stainless steel plate;

3. Sample racks feature stainless steel and aluminium alloy mesh frames for convenient sample access;

Structural Description

1. The chamber is manufactured using CNC equipment, featuring advanced craftsmanship, sleek lines, and an aesthetically pleasing design;

2. The chamber material is 1.0mm thick SUS304 stainless steel;

3. The internal air duct employs a single-cycle system with one imported axial fan, enhancing airflow velocity and heating capacity while significantly improving temperature uniformity within the test chamber;

4. Water supply and consumption: approximately 8 litres per day of tap or distilled water;

5. Heating method employs an internal water tank system, delivering rapid temperature rise and uniform thermal distribution;

6. Door features a single-direction pull mechanism for effortless, smooth closure;

7. Automatic water replenishment for the internal tank prevents dry-firing damage to heating elements;

8. Specimen racks constructed from stainless steel or aluminium alloy;

9. Unit base fitted with high-quality PU castors for mobility;

10. Drainage system utilises U-shaped sediment trap;

11. Specimen surfaces maintained parallel to UV lamp plane;

12. Internal spray system incorporates automatic nozzles with adjustable water pressure;

| Controller | TEMI P990 7-inch | South Korea |

| Light tube | UVA 340 | United States |

| Water pump | Stainless steel silent corrosion-resistant pump | Customised |

| Temperature sensor | VAISALA | Netherlands |

| Heater | Taiyi | Taiwan |

| Circulation motor | TECO | Taiwan |

| Angle contact switch | Tiande | Taiwan |

| Main power switch | Fuji | Japan |

| AC relay | Izumi | Japan |

| S.S.R | American Keda | United States |

1. GB/T 14522-1993 Accelerated Climatic Testing Methods for Plastics, Coatings and Rubber Materials for Mechanical Engineering Products

2. GB/T 16422.3-2022 Plastics – Laboratory light exposure test methods – Part 3: Fluorescent ultraviolet lamps

3. GB/T 16585-1996 Artificial climate ageing (fluorescent lamps) test method for vulcanised rubber

1. Over-temperature protection: When the internal temperature exceeds 93°C ±10%, the unit will automatically cut off power to the lamps and heating elements, entering a stabilised cooling phase;

2. Low water level alarm in the sump, preventing dry firing of the heating elements;

| Serial number | Accessory Name | Brand | Place of Origin | Quantity | Notes |

| 1 | Stainless Steel | 1.0mm | Domestic | 2 batches | Outer casing material |

| 2 | Stainless Steel | 1.0mm | Domestic | 2 batches | CNC-formed after bending |

| 3 | UV Lamp Tube | Philips | United States | 8 pieces | Inner casing material |

| 4 | Drive Motor | Wanxin | Taiwan | 1 unit | CNC-formed after bending |

| 5 | Speed Control Valve | Xinsanli | Taiwan | 1 unit | Excellent temperature resistance |

| 7 | Control Instrument | TIMI880 | South Korea | 1 unit | 40W |

| 3 | Voltmeter | Dial type | Domestic | 1 unit | |

| 9 | Switch | Mingwei | Taiwan | 1 unit | |

| 10 | Casters | Brake type | Domestic | 4 units | |

| 11 | Siemens PLC Module | BES7231-7PB22-OXA8 | Germany | 2 pieces | |

| 12 | AC Contactor | 20A | Chint | Pieces | |

| 13 | Heating Element | UL100 | Taiwan | Pieces | |

| 14 | Temperature Sensor | PT100 | Shanghai | 3 pieces | |

| 15 | Blackboard | Electrophoretic aluminium alloy finish | Custom-made | 4 pieces | |

| 16 | Thermal Protector | N6234 | Taiwan | 4 pieces | |

| 17 | Spray Water Circulation Pump | s-6512/220V | Shanghai Xishan | 4 pieces |

Products provided by famous enterprises are deeply trusted by users.

Shanghai Dengsheng Instrument Manufacturing Co., Ltd. is a high-tech enterprise integrating R&D, production, sales, and service. We specialize in the manufacture of high-end laboratory equipment, including ovens, incubators, industrial furnaces, and environmental test chambers.

We boast an 8,000-square-meter modern production facility, a dedicated R&D team, 23 national patents, and ISO-9001 quality management system certification. Our solutions are widely used in cutting-edge fields such as aerospace, semiconductors, biomedicine, automotive, and new materials. We have established in-depth partnerships with top universities and industry leaders, and our products are exported to many countries and regions around the world.

Adhering to the principles of "Integrity, Innovation, and Win-Win," we are committed to becoming your trusted partner with reliable quality and dedicated service.

2025/11/27

2025/11/27

2025/11/12

2025/11/12

2025/11/12

2025/11/12