Technical Specification for Salt Solution Cyclic Immersion Test Chamber

I. Technical Parameters of Salt Solution Cyclic Immersion Test Chamber:

Power Supply: AC 380V, 50Hz, 5kW

Drying Chamber Dimensions: 650mm × 650mm × 600mm (D × W × H)

Salt Immersion Chamber Dimensions: 650mm × 650mm × 400mm (D × W × H)

Designed Operating Temperature Range for Drying Chamber:

Ambient +8°C to 80°C ±2°C

Humidity: ≤50% (monitored display only, not controlled)

Time Setting Range: 0–999 minutes

Heating Power: 2 kW

Salt Immersion Chamber Temperature Range:

20°C to 50°C ±2°C

Time Setting Range: 0–999 minutes

Heating Power: 1.5 kW

| 1. Refrigeration Dehumidification System | Compressor | French Taikang hermetically sealed compressor, | |

| Cooling method | Air-cooled | ||

| Expansion valve | Danfoss thermal expansion valves are specifically designed for refrigeration applications, | ||

| Solenoid valve | ‘Imported Italian Castelli solenoid valves are primarily used for defrost regulation and refrigerant flow direction control in refrigeration systems’ | ||

| Condenser | ‘Air-cooled condensers employ high-torque, low-speed fans, resulting in low noise levels. V-type air-cooled condensers further offer advantages including substantial cooling capacity, compact footprint, and aesthetically pleasing design.’ | ||

| Evaporator | Zhejiang Weisheng | ||

| Drying filter | ‘Danfoss dryer filter characteristics: 80% 3A molecular sieve and 20% activated alumina. Maximum operating pressure up to 42 bar.’ | ||

| Refrigeration Principle | Refrigeration system principle | The refrigeration cycle employs the reverse Carnot cycle, comprising two isothermal processes and two adiabatic processes, as follows: the refrigerant undergoes adiabatic compression within the compressor to a higher pressure, consuming work and raising the discharge temperature. Subsequently, the refrigerant undergoes isothermal heat exchange with the surrounding medium via the condenser, transferring heat to the surroundings. The refrigerant then undergoes adiabatic expansion through the throttle valve, performing work and lowering its temperature. Finally, the refrigerant absorbs heat isothermally from a higher-temperature object via the evaporator, thereby lowering the temperature of the cooled object. This cycle repeats continuously to achieve the cooling effect. | |

| The design of refrigeration systems incorporates energy regulation technology, an effective approach that ensures the normal operation of refrigeration units while simultaneously enabling efficient adjustment of both energy consumption and cooling capacity. This results in the operating costs of the refrigeration system being reduced to a more economical level. | |||

| In refrigeration technology, we boast seasoned engineers with years of proven expertise, rational configurations, and flawless industrial manufacturing. The core of refrigeration lies in configuration and manufacturing processes. We firmly believe China's technology will continually advance, offering mid-range German products to bring greater convenience to the domestic market. |

|||

| 2. Control System | |||||

| 2.1 Instrument Overview | True Colour Touchscreen Display Control Mode: Programmable/Fixed Value Capable of programming 30 sets of programmes, each set supporting up to 30 segments; USB communication interface for computer connectivity (optional) Display Language: Switchable between Chinese and English |

||||

| 2.2 Fixed-Value Power Cut Method | Operating Mode: Select programme operation or constant-value operation Power Failure Mode: Stop: Programme/constant-value halt; Cold Start: Commences operation from the first segment; Hot Start: Resumes operation for the duration of the segment running prior to power failure Lock: Configure keyboard input lock or unlock Backlight: Set automatic backlight illumination shutdown time |

||||

| 2.3 Curve Display Screen | Display temperature and humidity operating curves Click to enlarge or reduce the graph |

||||

| 3. Fault Alarm System (Optional) | |||||

| Equipment Safety Protection | Studio over-temperature; heater short-circuit, overload protection, Compressor over-pressure; overload; overcurrent, overheat protection System earth leakage protection Main power supply phase sequence and phase loss protection System earth leakage protection Fan overheat protection Sample over-temperature |

||||

| 4. Brief Introduction to Selected Electrical Components | |||||

| Small relays | Shanghai Chint small relays employed | ||||

| AC contactors | Chint brand AC contactors employed | ||||

| Solid-state devices | Shanghai Renmin Electric solid-state relays employed | ||||

| Time delay relays | Upon power disconnection, the relay initiates a delay period. After reaching the preset duration, the relay activates one set of delayed contacts | ||||

| Circuit breakers | Shanghai Renmin Electric circuit breakers employed | ||||

| Temperature sensors | Taiwan Yifan PT100 sensors employed | ||||

II. Functional Description and Operational Workflow

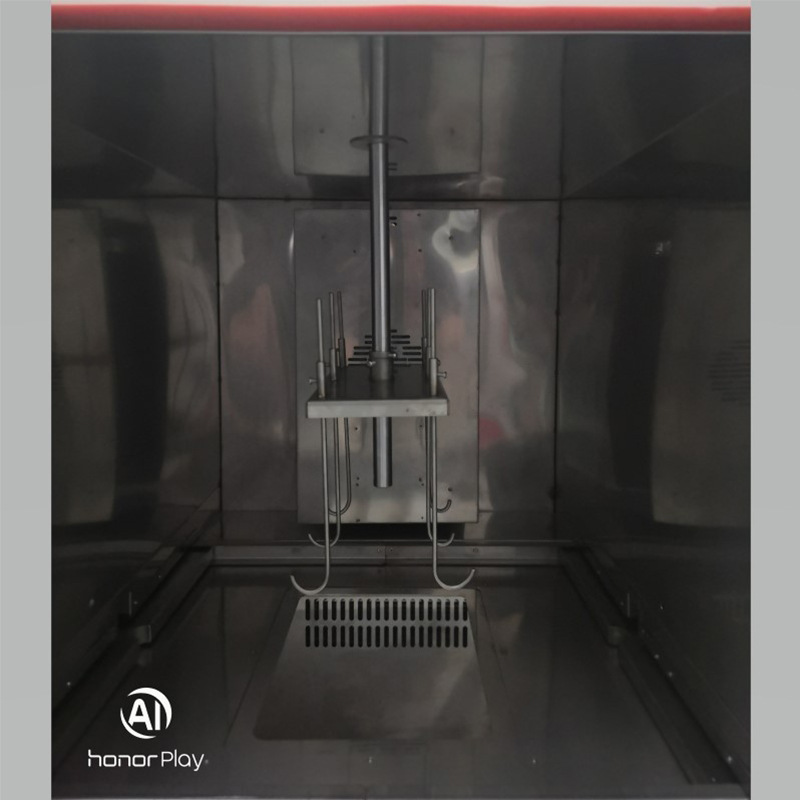

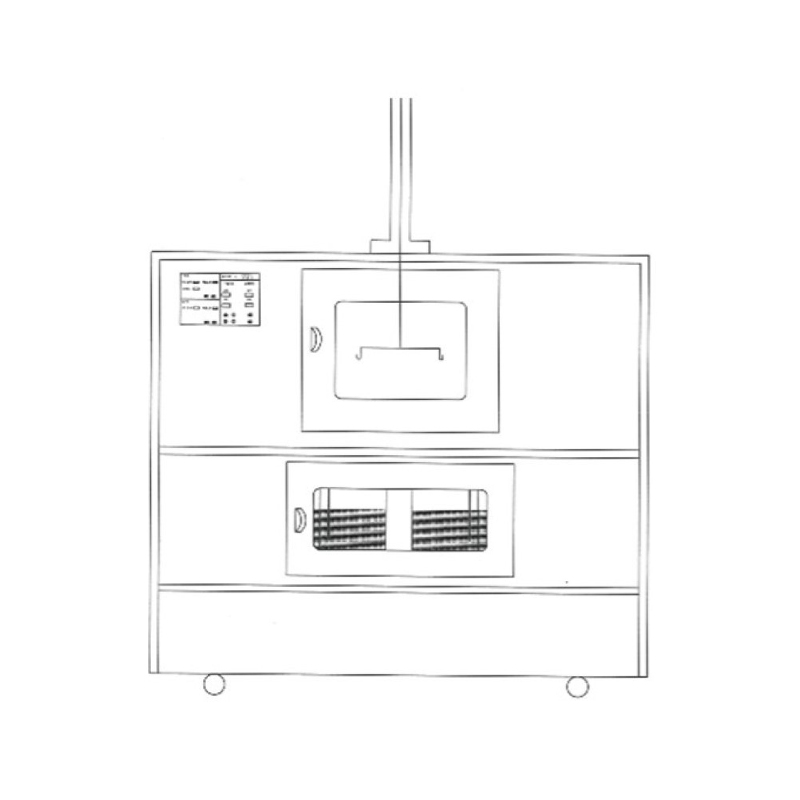

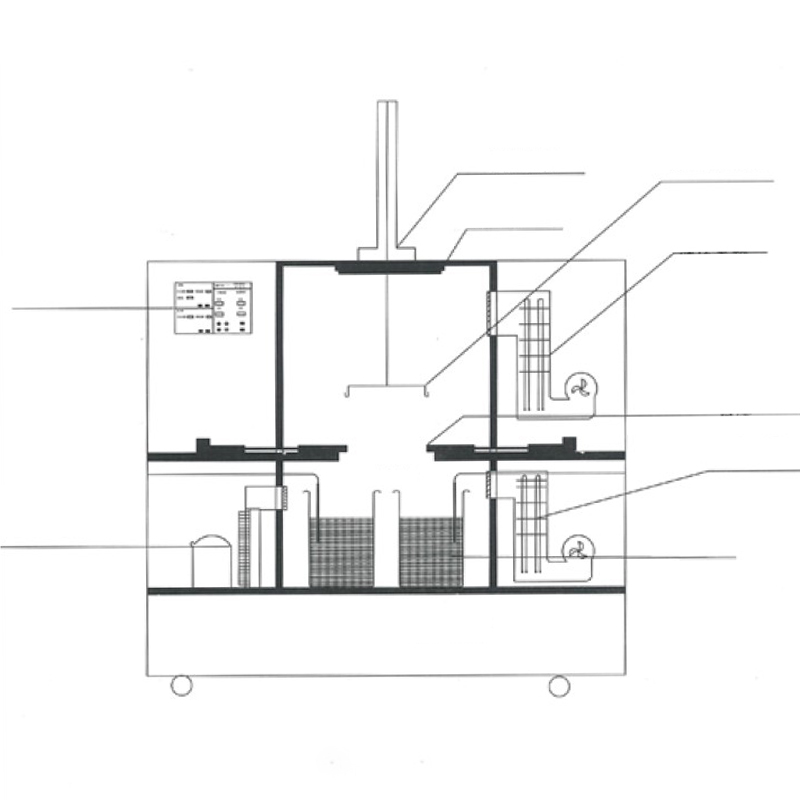

2.1. This salt solution immersion test chamber is designed with an upper drying chamber and a lower salt solution tank. The partition door automatically opens to maintain dryness and meet immersion test requirements, ensuring independent temperature and humidity control within both chambers. The inner chamber is constructed from 1.2mm thick to enhance the working chamber's corrosion resistance. The outer casing is constructed from 1.5mm thick carbon steel plate with a spray-coated finish. Ultra-fine ceramic fibre wool insulation fills the cavity between the inner chamber and outer casing for thermal retention. Both drying chamber and salt immersion chamber doors are designed as left-hinged for convenient specimen removal and insertion. Door frames incorporate high/low-temperature resistant seals and feature large-area tempered double-glazed viewing windows for real-time observation. Stainless steel handles enhance corrosion resistance. Salt immersion solution containers are fabricated from 316L stainless steel with internal/external PTFE coating.

2.2. For alternating testing of specimens between upper and lower chambers, an electric push rod mounted atop the drying oven lifts and lowers specimens. The specimen rack, fabricated from 316L stainless steel, accommodates six samples. An electrically operated partition door between the drying oven and salt immersion chamber automatically opens and closes according to the experimental sequence, with additional manual override buttons for temporary operation.

2.3 The drying chamber's inner lining is fabricated from 316L stainless steel. The outer casing employs carbon steel plate with a spray-coated finish. The door opens to the left, fitted with high/low-temperature resistant sealing strips. A large tempered glass viewing window facilitates observation. The heating system incorporates internal stainless steel heating tubes. The air duct design features right-side air discharge, with air returning via the left side. An imported high-temperature resistant fan motor ensures forced convection with vertical diffusion circulation, eliminating dead zones and achieving uniform temperature distribution throughout the chamber. A Class A high-precision PT100 platinum resistance thermometer provides sensitive temperature sensing for superior control accuracy. Real-time humidity monitoring is integrated (as hot-air drying eliminates the need for separate dehumidification equipment, chamber humidity remains ≤50%).

2.4. The interior chamber of the salt spray chamber is constructed from 316L stainless steel. The outer casing employs carbon steel plates with a spray-coated finish. The salt solution tank is fabricated from 316L stainless steel, with both interior and exterior surfaces coated in PTFE or constructed from PTFE material to ensure corrosion resistance. Temperature sensors utilise Grade A high-precision platinum resistance sensors for direct measurement of the salt solution temperature. These sensors are fully encapsulated in PTFE to prevent reaction with the salt solution. Given the operational temperature requirement of 20°C to 50°C, the salt immersion chamber incorporates dual systems: a refrigeration cycle and a heating cycle. The heating cycle employs the same method as that used in drying ovens.

2.5. Equipment control employs a human-machine interface with PLC programming, enabling cyclical operation according to experimental requirements. Temperature control precision within the drying and salt immersion chambers is maintained to ±1°C. A humidity monitor is installed in the drying chamber for real-time display of operating humidity (though humidity is not controlled). Both drying and salt immersion chambers can be started or stopped independently. All external wiring is fitted with high-temperature resistant insulating sleeves to prevent ageing.

2.6. In accordance with test requirements, specimens undergo periodic drying in the drying oven and immersion in the salt immersion chamber. Prior to each cycle, the drying oven and salt immersion chamber operating temperatures are individually set, and their respective temperature control systems activated. Once the chambers reach the required working temperatures, the drying duration (e.g., 50 minutes) and immersion duration (e.g., 20 minutes) are configured, followed by the in and activate their respective temperature control systems. Once the chambers reach the required operating temperatures, set the drying duration (e.g., 50 minutes) and immersion duration (e.g., 20 minutes), along with the number of cycles. Press the start button (under normal conditions, the sample rack is positioned in the drying chamber). The test specimens will then undergo periodic drying and immersion cycles according to the programmed schedule. Upon completion of the drying period (e.g., 50 minutes), the partition door between the drying and immersion chambers opens. The electric push rod positioned atop the chamber then lowers the test specimen into the immersion chamber. Simultaneously, the cover at the top of the push rod seals the specimen passage, isolating the upper and lower chambers. When the immersion period (e.g., 20 minutes) concludes, the electric push rod lifts the specimen back into the drying chamber. The intermediate partition door then closes automatically, re-isolating the two chambers. This sequence constitutes one cycle, which repeats according to the preset number of cycles until the test concludes. Furthermore, the time for each specimen to be fully submerged or retrieved shall not exceed 2 minutes. Additionally, to accommodate special requirements, this apparatus is equipped with separate open and close buttons for the intermediate partition door. The specimen holder also features a momentary lift button, enabling the specimen to be raised or lowered as required for operational needs.

Español

Español  عربى

عربى