| Product Name | Automatic Vacuum Drying Oven | ||

| Model | HTF-DZ215V | ||

| Key Technical Specifications | Temperature control range | RT+10~200°C | |

| Temperature stability | ±2°C | ||

| Temperature resolution | 0.1°C | ||

| Nitrogen inlet diameter | 14mm | ||

| Filter | Class 10,000 | ||

| Heating method | External heating | ||

| Cooling method | Natural cooling | ||

| Cooling rate | None | ||

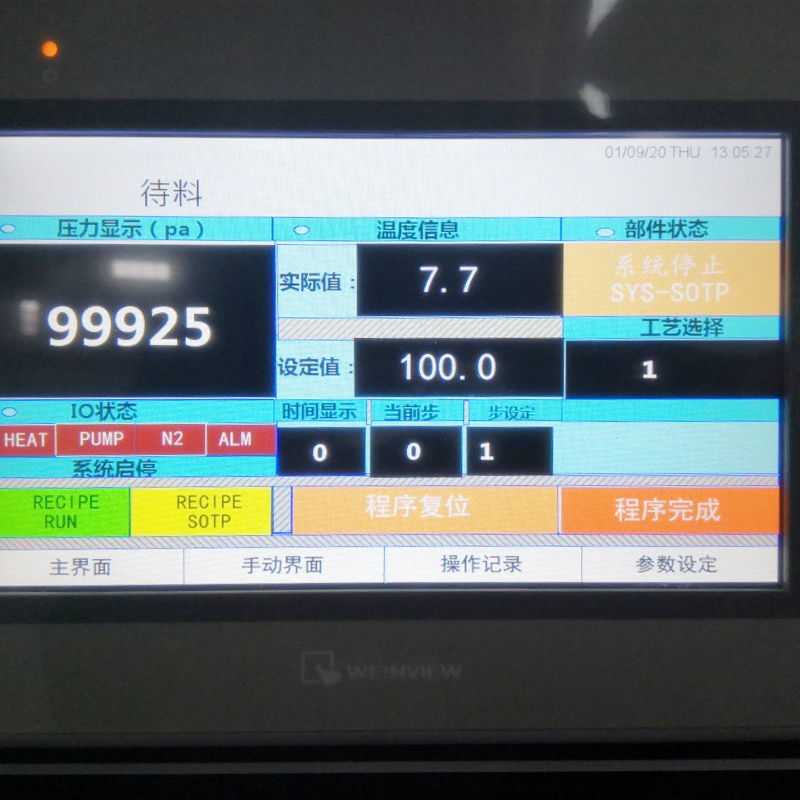

| Controller | Touchscreen PLC Industrial Control | ||

| Vacuum gauge | Digital Vacuum Gauge | ||

| Vacuum range | 50Pa-101KPa | ||

| Vacuum control method | Setpoint Control | ||

| Inner chamber dimensions | W*D*H (mm) ≥560*640*600 | ||

| Main unit external dimensions | W*D*H (mm) ≈720*820*1750 | ||

| Inner chamber volume | 215L | ||

| Observation window | 300x350mm, constructed with inner reinforced tempered glass and outer high-transparency acrylic panels | ||

| Partition | 6 tiers, single-tier load capacity 30kg (shelves feature perforated stainless steel plates) | ||

| Support frame | 6 tiers, clearance height 70mm | ||

| Vacuum pump | Imported oil-free vacuum pump | ||

| Power supply voltage | 220V/50Hz | ||

| Power consumption | 2500W | ||

| Temperature control system | Features a microprocessor-based PID logic temperature controller for sustained operation. Electronic components utilise products from Chint and Shanghai People Electric, ensuring long-term stability and reliability. | ||

| Heating element | Premium HRE alloy heating wire is embedded within corrosion-resistant SUS304 stainless steel tubing, guaranteeing extended heating element lifespan while providing electrical leakage protection. | ||

| Temperature sensing element | High-precision PT-100 thermocouple | ||

| Housing material | SUS304 stainless steel (1mm thickness) | ||

| Inner tank material | 316L corrosion-resistant stainless steel plate (3mm thickness) | ||

| Equipment Structure Description | The main unit dimensions are 720 × 820 × 1750mm. The main unit is fitted with four Fuma castors and four fixed support legs for easy mobility and secure positioning. The control system is externally mounted on the left or right side of the enclosure. The chamber corners feature rounded corners with no blind spots for convenient cleaning. The chamber interior comprises six tiers, each with a minimum clearance height of 70mm (effective usable height), and a minimum single-tier area of 555 × 635mm. | ||

| Control System Description | with no dead corners for easy cleaning. The chamber interior comprises 6 tiers with a minimum clearance height of 70mm (effective usable height) per tier. Each tier has a minimum area of 555 × 635mm, accommodating two standard baskets (480 × 250 × 50mm) per tier. Full load capacity is 12 standard baskets. The main unit door opens to the right, conforming to ergonomic principles." | ||

| Equipment Operation Process Description | The equipment employs PLC industrial control programming. Programmable control encompasses vacuum pump start/stop status, vacuum level setting, vacuum hold duration, inert gas filling time, inert gas solenoid valve closure time, and heating cycle initiation/termination. | ||

| Data Storage and Export | Single-stage operation: | ||

| Printing System | Step 1: Set vacuum level (assumed value: 80 kPa) | ||

| Self-Tuning Function | Step 2: Set target temperature and post-reach dwell time (assumed target: 200°C) | ||

| Real-Time Alarms | Step 3: Initiate vacuum or heating (concurrently possible) → Achieve target vacuum level → Vacuum pump automatically ceases operation | ||

| Safety Assurance | set temperature and post-temperature-reach operation time (assumed temperature: 200°C) → Step 3: | ||

| Equipment Operating Environment | Evacuate vacuum or heat (can be performed concurrently) → Upon reaching set vacuum value, vacuum pump | ||

| Warranty Period | automatically stops while heating continues. Once temperature setpoint is attained and temperature | ||

| Post-installation Maintenance | operation time elapses, equipment automatically halts. | ||

| After-sales and Maintenance Response Time | (Note: During heating, air expansion within the chamber reduces vacuum level, triggering automatic | ||

| Configuration | vacuum pump restart to replenish vacuum. Heating or constant-temperature operation proceeds normally.) | ||

Customized Drying Oven

Customized Drying Oven

Customized Drying Oven

2025-12-18

Customised Fully Automatic Nitrogen-Filled Vacuum Oven

Send Message

- CONTACT

-

- No. 119, Qingliang Avenue, Yaozhuang Town, Zhejiang, China.

- [email protected] ( Email )

- +86-13671719019 ( Phone )

- +86-021-57440136 ( Tel )

- PRODUCT

-

- Drying Oven Series

- Vacuum Box Series

- Explosion-proof Series

- High-temperature Furnace Series

- Incubator Series

- Test Chamber Series

- Other Series

- Forced Air Drying Oven

- Resistance Furnace

- Vacuum Tube Furnace

- Mold Incubator

- Vacuum Atmosphere Furnace

- Biochemical Incubator

- Carbon Dioxide Incubator

- Explosion-Proof Vacuum Drying Oven

- High and Low Temperature Test Chamber

- MOBILE

Copyright ©

Shanghai Dengsheng Instrument Manufacturing Co., Ltd.

All Rights Reserved. Laboratory Equipment Manufacturers

Back to Top

Back to Top

Español

Español  عربى

عربى