2025/11/27

2025/11/27

With a deep commitment to the global market, Shanghai Dengsheng Instruments has earned international acclaim for its quality.

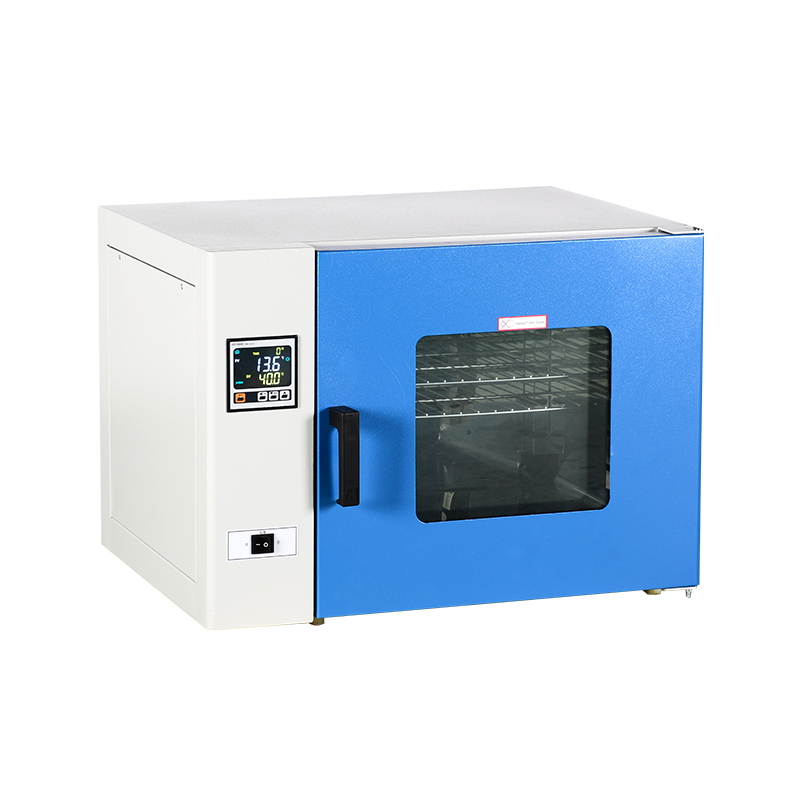

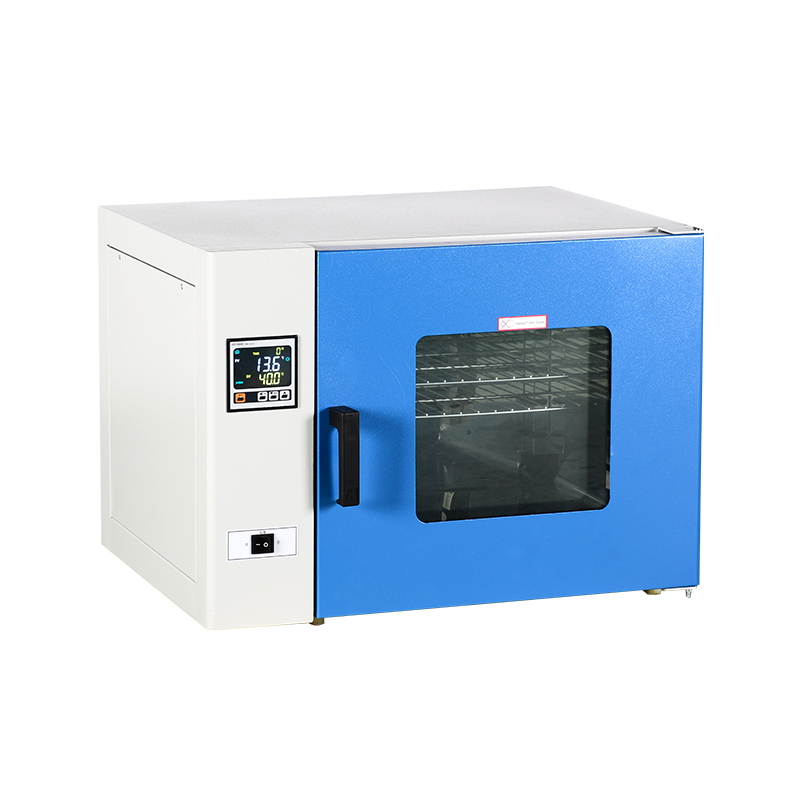

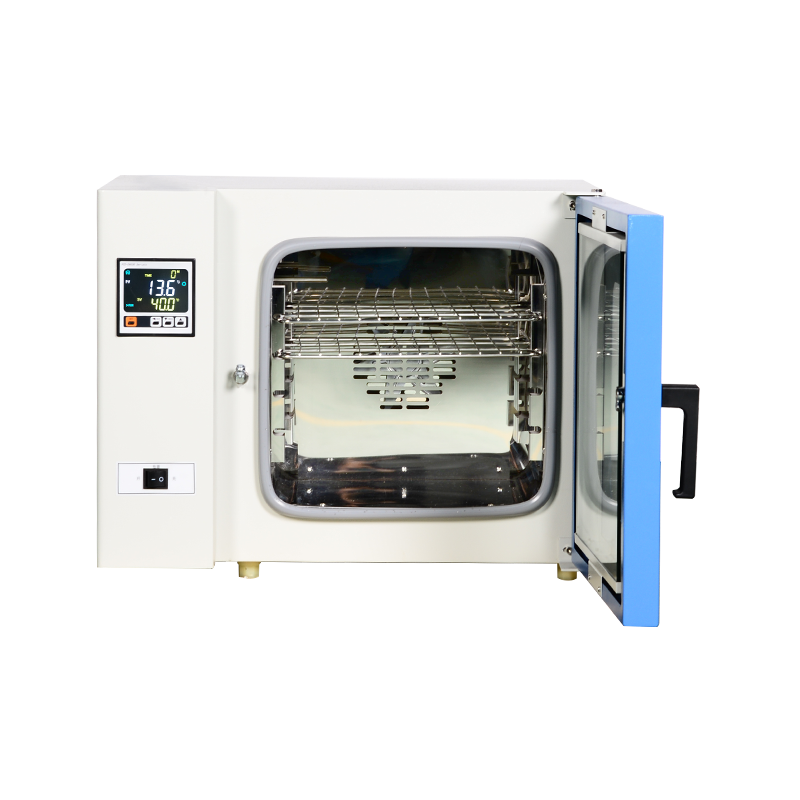

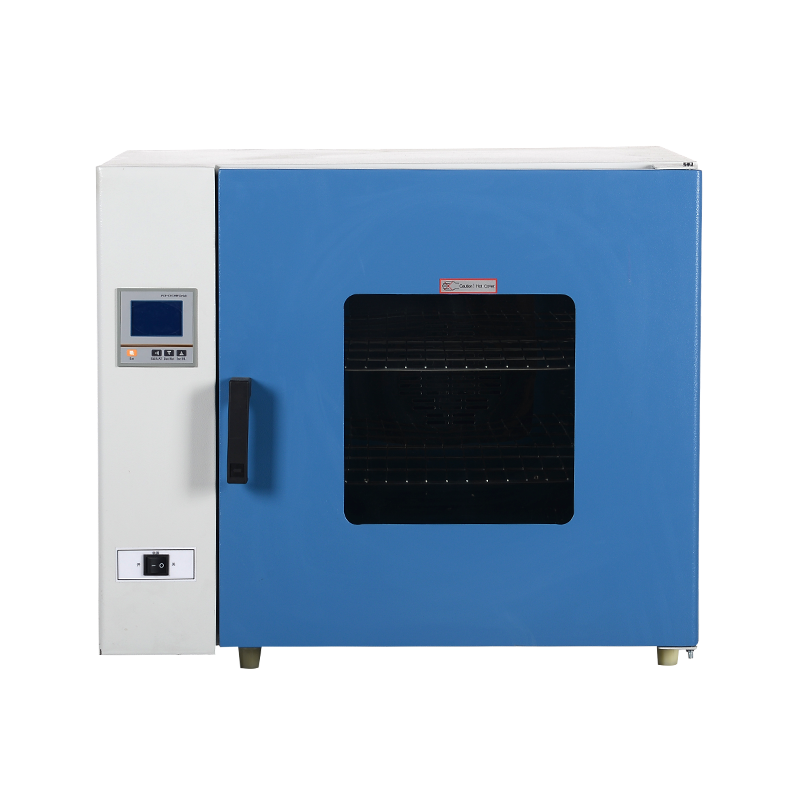

Electric heating drying ovens, also known as electric drying ovens, constant temperature drying ovens, and hot air circulating drying ovens, are available in vertical and tabletop models. They are laboratory and industrial equipment that uses electric heating and a circulating fan to control temperature. Primarily used for sample drying, material heat treatment, or providing a constant temperature environment, they are widely used in universities, enterprises, research institutes, and laboratories for drying, baking, wax melting, heat treatment, and sterilization. They can also be used in industrial production processes such as aging, curing, and secondary vulcanization. This product is not suitable for volatile substances or flammable and explosive solvents to avoid explosions.

Adopts a microcomputer-integrated intelligent temperature control system with a built-in PID logic module, possessing constant current, constant pressure, constant resistance, constant power, and combined load functions, achieving excellent response speed and control accuracy;

LCD screen display interface, providing precise and reliable temperature control, simultaneously displaying set temperature, operating temperature, constant temperature time, working status, fault codes, and other information;

Features a scheduled operation function with selectable timing functions (none, constant temperature timing, running timing), selectable timing direction (forward or countdown), selectable timing unit (minutes, hours), and a buzzer sound to indicate the end of the timer (the reminder time is settable);

Modular control system with self-diagnosis upon startup, timing function, self-tuning function, temperature deviation compensation function, etc. The temperature over-limit control module is linked with the over-temperature alarm system, automatically cutting off the heating power and triggering an audible and visual alarm when the temperature exceeds the limit;

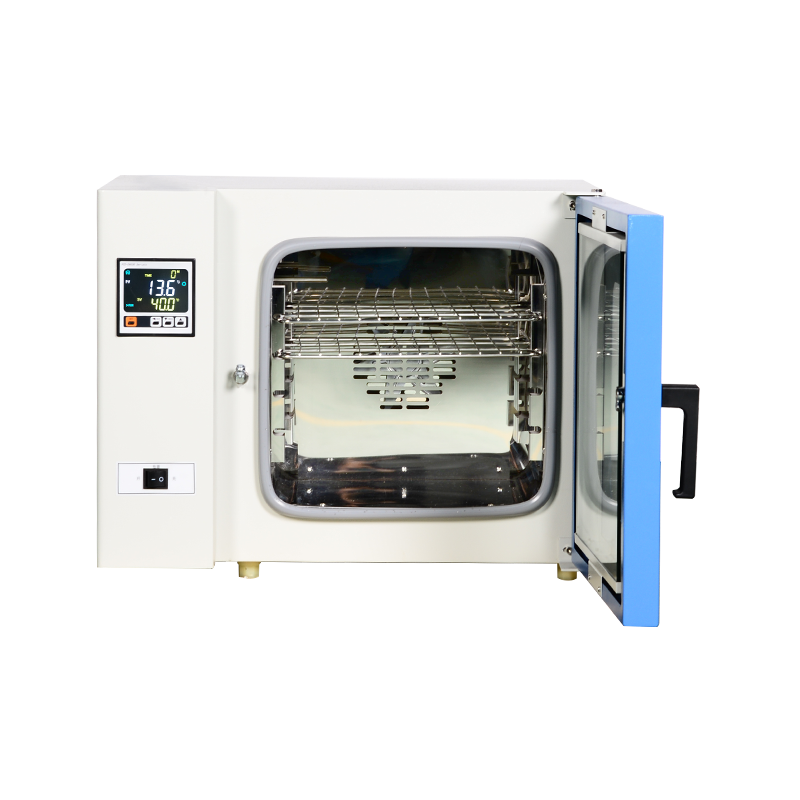

Independently developed air duct structure supplemented by a low-noise circulating fan forms a high-efficiency hot air circulation system with horizontal airflow mode, allowing dry, hot air to directly pass over the material. Effectively improves drying efficiency;

Rear-mounted automatic air inlet and outlet vents automatically discharge water vapor from the chamber, eliminating the hassle of manual adjustment;

High-quality mirror-finish stainless steel inner liner, with a high-quality cold-rolled steel outer shell and solid powder electrostatic spraying, providing weather resistance, corrosion resistance, and anti-static properties, eliminating VOC emissions and ensuring a healthy laboratory environment;

SUS304 dry-type stainless steel heating tubes provide heating, with heat energy evenly transferred to the stainless steel tube wall through a magnesium oxide sand layer, achieving a heat conversion efficiency of over 95% and a service life of over 20,000 hours;

Door seals are made of high-temperature resistant silicone rubber, supplemented with high-quality 120-count ultra-fine ceramic fiber cotton insulation material, greatly improving the overall insulation performance and achieving excellent energy-saving effects;

Supports operational data recording function, with freely adjustable recording intervals and data export (optional: USB interface);

Supports customizable 30-segment temperature curves to meet complex experimental needs (optional: 30-segment programmable controller);

Supports stepless fan speed adjustment, adaptable to heat treatment operations of various materials (optional: fan speed controller)

Desktop air-blowing drying oven

| Model | DS-30H | DS-50H | DS-70H | DS-140H | DS-240H | DS-270H |

| DS-35H | DS-55H | DS-75H | DS-145H | DS-245H | DS-275H | |

| Controller | 4.3-inch LCD digital display (PID smart control) | |||||

| Temperature range | Type 0: RT +10~250℃ Type 5: RT +10~300℃ | |||||

| Discrimination rate / volatility | 0.1℃/≤1℃ | |||||

| Temperature uniformity | ±1.5℃ (measured at 100℃) | |||||

| Sensor | PT100 platinum resistance | |||||

| Round-robin mode | Horizontal air supply | |||||

| Time range | 1~9999min | |||||

| Smart Security | Power-on self-test, power-off memory, overheating alarm and heating stop, sensor deviation correction, self-adjustment, internal parameter lock | |||||

| Inner liner size (mm) | 340*330*320 | 420*350*350 | 450*400*450 | 550*450*550 | 600*600*650 | 600*600*750 |

| Outline dimension mm | 625*540*500 | 705*610*530 | 735*610*630 | 835*670*730 | 880*800*830 | 880*800*930 |

| Volume | 35L | 51L | 72L | 136L | 234L | 270L |

| Gross/Net Weight in kg | 37/25 | 48/35 | 52/38 | 74/59 | 87/72 | 102/87 |

| Supply voltage | AC220V/50Hz/10A | AC220V/50Hz/15A | ||||

| Power :KW | 0.85 | 1 | 1.5 | 2 | 2.5 | |

| Number of partitions | 2 | |||||

| Work environment | 0~45℃ | |||||

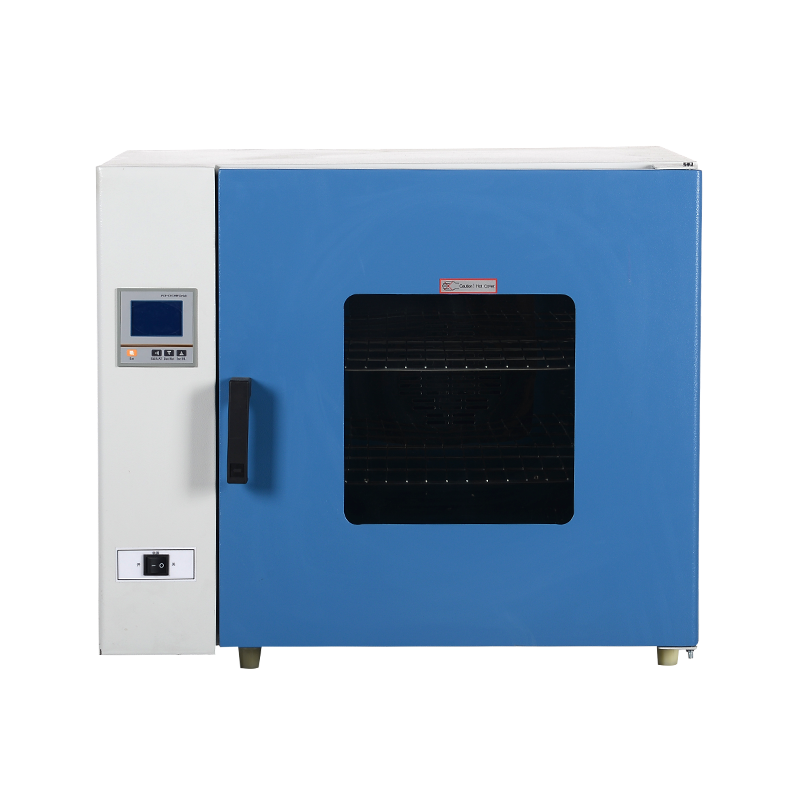

Vertical air-drying oven

| Model | DS-30HL | DS-70HL | DS-140HL | DS-240HL | DS-420HL | DS-620HL | DS-640HL | DS-960HL | DS-1000HL | DS-1050HL | ||||||

| DS-35HL | DS-75HL | DS-145HL | DS-245HL | DS-425HL | DS-625HL | DS-645HL | DS-965HL | DS-1005HL | DS-1055HL | |||||||

| Controller | 4.3-inch LCD digital display (PID smart control) | |||||||||||||||

| Temperature range | Type 0: RT +10~250℃ Type 5: RT +10~300℃ | |||||||||||||||

| Discrimination rate / volatility | 0.1℃/≤1℃ | |||||||||||||||

| Temperature uniformity | ±1.5℃ (measured at 100℃) | |||||||||||||||

| Sensor | PT100 platinum resistance | |||||||||||||||

| Round-robin mode | Horizontal air supply | |||||||||||||||

| Time range | 1~9999min | |||||||||||||||

| Smart Security | Power-on self-test, power-off memory, overheating alarm and heating stop, sensor deviation correction, self-adjustment, internal parameter lock | |||||||||||||||

| Inner tank | Wide | 300 | 400 | 450 | 500 | 600 | 800 | 800 | 1000 | 1000 | 1000 | |||||

| Size | ||||||||||||||||

| MM | ||||||||||||||||

| Deep | 300 | 420 | 550 | 600 | 550 | 600 | 800 | 600 | 1000 | 800 | ||||||

| Gao | 345 | 445 | 550 | 750 | 1300 | 1300 | 1000 | 1600 | 1000 | 1300 | ||||||

| Appearance | Wide | 445 | 545 | 640 | 680 | 780 | 980 | 980 | 1140 | 1140 | 1140 | |||||

| Size | ||||||||||||||||

| MM | ||||||||||||||||

| Deep | 470 | 580 | 710 | 800 | 750 | 750 | 980 | 780 | 1180 | 980 | ||||||

| Gao | 700 | 800 | 900 | 1200 | 1750 | 1750 | 1490 | 1990 | 1390 | 1690 | ||||||

| Volume | 31L | 75L | 136L | 225L | 429L | 625L | 640L | 960L | 1000L | 1040L | ||||||

| Gross weight in kilograms (kg) | 39/27 | 59/47 | 87/75 | 110/95 | 175/160 | 245/225 | 252/230 | 293/255 | 294/255 | 297/257 | ||||||

| Supply voltage | AC220V/10A | 220V/15A | 380V/15A | AC380V/20A | ||||||||||||

| Power rating | 0.85KW | 1KW | 1.5KW | 2KW | 3KW | 4.5KW | 6KW | |||||||||

| Number of partitions | 2 | 3 | ||||||||||||||

| Work environment | 0~45℃ | |||||||||||||||

Products provided by famous enterprises are deeply trusted by users.

Shanghai Dengsheng Instrument Manufacturing Co., Ltd. is a high-tech enterprise integrating R&D, production, sales, and service. We specialize in the manufacture of high-end laboratory equipment, including ovens, incubators, industrial furnaces, and environmental test chambers.

We boast an 8,000-square-meter modern production facility, a dedicated R&D team, 23 national patents, and ISO-9001 quality management system certification. Our solutions are widely used in cutting-edge fields such as aerospace, semiconductors, biomedicine, automotive, and new materials. We have established in-depth partnerships with top universities and industry leaders, and our products are exported to many countries and regions around the world.

Adhering to the principles of "Integrity, Innovation, and Win-Win," we are committed to becoming your trusted partner with reliable quality and dedicated service.

2025/11/27

2025/11/27

2025/11/12

2025/11/12

2025/11/12

2025/11/12