2025/11/27

2025/11/27

With a deep commitment to the global market, Shanghai Dengsheng Instruments has earned international acclaim for its quality.

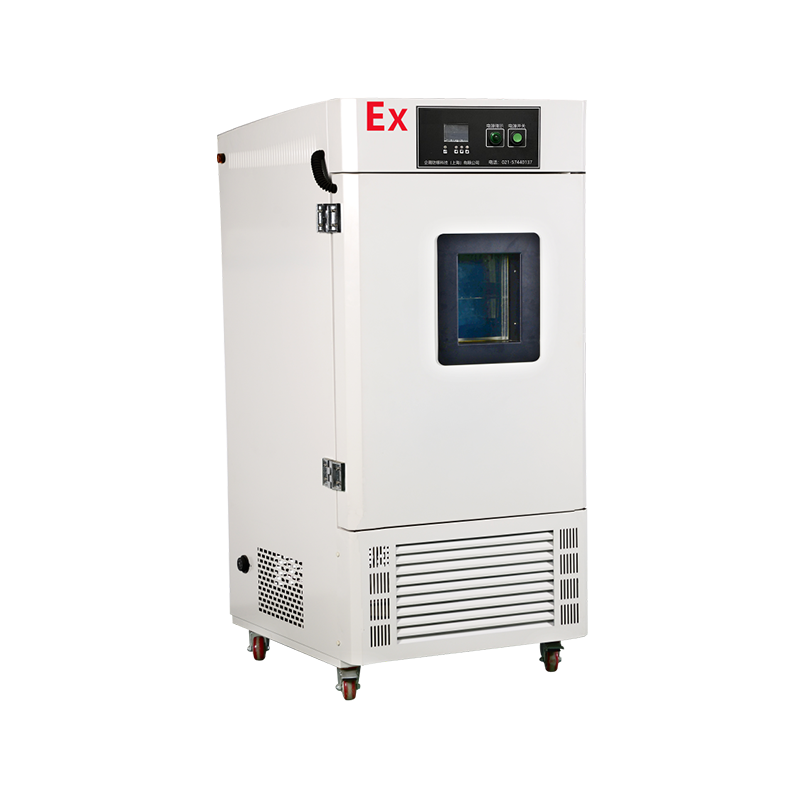

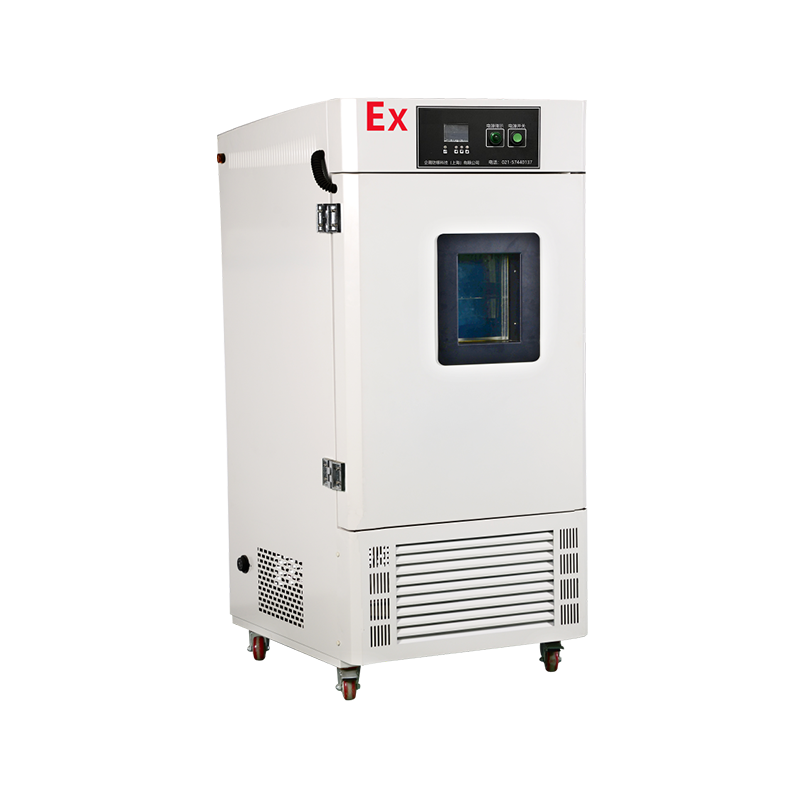

Explosion-proof low-temperature chambers, also known as explosion-proof incubators, are dual-temperature incubation or storage units suitable for research institutes, electronics, chemical laboratories, hospitals, blood banks, and disease control centres. They are widely employed for storing culture media, serum, pharmaceuticals, and for microbial cultivation and environmental testing. These chambers may also be utilised for low-temperature testing of electronic components, resins, rubber and plastics, toys, and specialised materials.

1. The product complies with IIB explosion-proof standards and is suitable for hazardous locations with explosive gas mixtures in temperature classes T1 to T4. It achieves an explosion-proof rating of IIB T4. The product has been certified as compliant by the ****** Electrical Safety Quality Inspection and Testing Centre and holds a valid ********* explosion-proof certification;

2. The electrical control system employs a composite explosion-proof technology combining flameproof and encapsulated designs. The operating switch is a passive switch that generates no mechanical sparks during operation, ensuring safe and reliable use. Sensors are equipped with external safety barriers for explosion-proof isolation;

3. The explosion-proof digital temperature controller features a menu-driven interface with a 5.7-inch LCD screen. It includes a standard auto-lock function to prevent accidental operation; A single screen displays set temperature, operating temperature, constant temperature duration, heating status, and other information, ensuring straightforward operation. The microprocessor-based PID control system delivers precise temperature regulation with minimal fluctuation;

4. The intelligent microprocessor temperature control system incorporates PID logic operations. Based on calculation results, it automatically corrects temperature deviations to achieve precise control;

5. Incorporates a programmable start function with multiple timing modes: forward countdown, reverse countdown, constant temperature timing, and start-up timing. Timing units are selectable in minutes or hours;

6. Core components (refrigeration cycle) utilise imported brand compressors and circulation fans. The compressor employs cast-sealed explosion-proof technology for safety and reliability. Utilises fluorine-free, environmentally friendly refrigerant to foster a healthy laboratory environment;

7. The internal air circulation system employs a high-temperature resistant, low-noise explosion-proof axial fan for forced circulation. The refrigeration system features a classic arrangement proven stable through years of market testing, ensuring safety and reliability;

8. Automatically monitors operational status. Upon exceeding the limit temperature, heating is automatically cut off with audible and visual alarms alerting operators to ensure uninterrupted experiments. Parameters are automatically saved during emergencies, with power-on recovery functionality. Additionally, it includes sensor self-diagnosis, over-temperature, and fault alarm capabilities;

9. The inner chamber employs 304 mirror-finished stainless steel with rounded corners, while the outer shell utilises premium cold-rolled steel plate with electrostatic powder coating. The finish is durable, long-lasting, and anti-static;

10. Magnetic seal door facilitates easy opening with excellent sealing performance; adjustable shelves optimise space utilisation;

11. Double-door construction allows 360-degree observation of the working chamber through the inner tempered glass door when the outer door is open, without affecting internal temperature.

| Model | HLTS-9110EX | HLTS-9115EX | HLTS-9125EX | HLTS-9130EX | HLTS-9150EX |

| Explosion-proof rating | IIBT4 | ||||

| Temperature range | -20~65℃ | ||||

| Temperature resolution | 0.1℃ | ||||

| Temperature fluctuation | High temperature: ±0.5°C Low temperature: ±1°C | ||||

| Temperature control method | 5.7-inch widescreen LCD digital display | ||||

| Circulation method | Forced convection | ||||

| Compressor | Air-cooled hermetic compressor | ||||

| Refrigerant | CFC-free and environmentally friendly | ||||

| Sterilisation method | UV sterilisation | ||||

| Defrosting method | Intelligent control with automatic defrosting | ||||

| Power supply voltage | AC220V/10A | AC220V/15A | |||

| Timing range | 1~9999min | ||||

| Operating mode | Fixed-value, fixed-time operation | ||||

| Internal cavity (mm) | 450x380x590 | 480x400x780 | 580x500x850 | 580x540x950 | 700X700X1020 |

| External dimensions (mm) | 575x605x1160 | 605x625x1375 | 705x725x1540 | 705x765x1640 | 850X995X1780 |

| Volume | 100L | 150L | 246L | 297L | 500L |

| Gross/net weight (kg) | 113/98 | 130/115 | 180/155 | 190/165 | 286/255 |

| Standard shelves | 2 | 3 | |||

| Rated power | 1.2KW | 1.2KW | 1.5KW | 2KW | 2.5KW |

1. GB/T 3836.1-2021 Explosive Atmospheres - Part 1: Equipment - General Requirements

2. GB/T 3836.2-2021 Explosive Atmospheres - Part 2: Equipment Protected by Flameproof Enclosures ‘d’

3. GB/T 3836.9-2021 Explosive Atmospheres - Part 9: Equipment Protected by Encapsulation ‘m’

4. GB/T 2423.1-2008 Environmental Testing of Electrical and Electronic Products - Part 2: Test Methods - Test A: Low Temperature

5. GB/T 20154-2014 Low-Temperature Storage Chambers

6. GB/T 10589-2008 Technical Conditions for Low-Temperature Test Chambers

1. Over-temperature alarm

2. Overcurrent and overload protection

3. Rapid fuse

4. Earth leakage circuit breaker

Products provided by famous enterprises are deeply trusted by users.

Shanghai Dengsheng Instrument Manufacturing Co., Ltd. is a high-tech enterprise integrating R&D, production, sales, and service. We specialize in the manufacture of high-end laboratory equipment, including ovens, incubators, industrial furnaces, and environmental test chambers.

We boast an 8,000-square-meter modern production facility, a dedicated R&D team, 23 national patents, and ISO-9001 quality management system certification. Our solutions are widely used in cutting-edge fields such as aerospace, semiconductors, biomedicine, automotive, and new materials. We have established in-depth partnerships with top universities and industry leaders, and our products are exported to many countries and regions around the world.

Adhering to the principles of "Integrity, Innovation, and Win-Win," we are committed to becoming your trusted partner with reliable quality and dedicated service.

2025/11/27

2025/11/27

2025/11/12

2025/11/12

2025/11/12

2025/11/12