2025/11/27

2025/11/27

With a deep commitment to the global market, Shanghai Dengsheng Instruments has earned international acclaim for its quality.

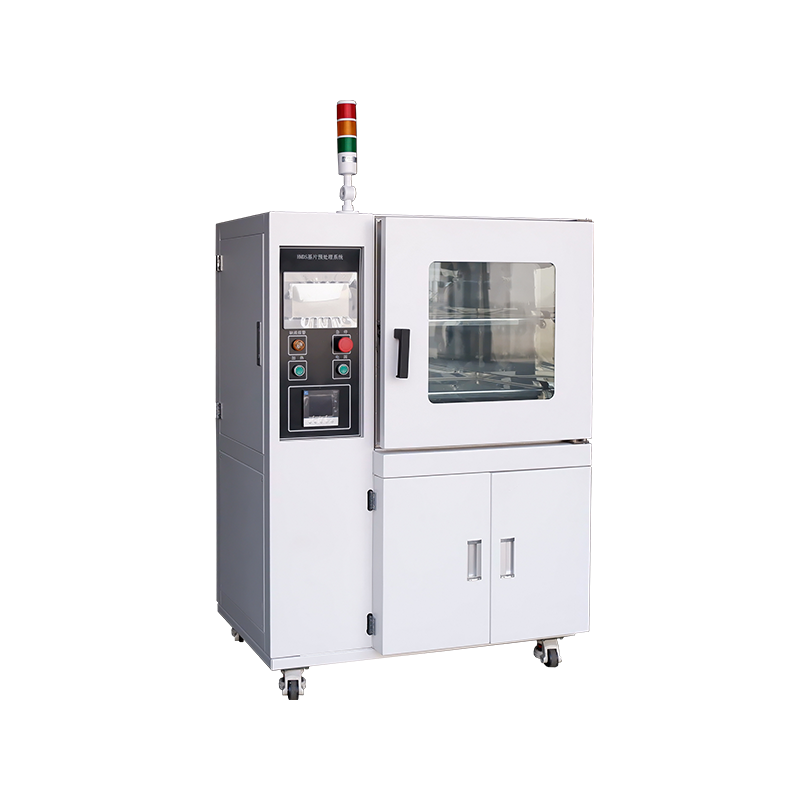

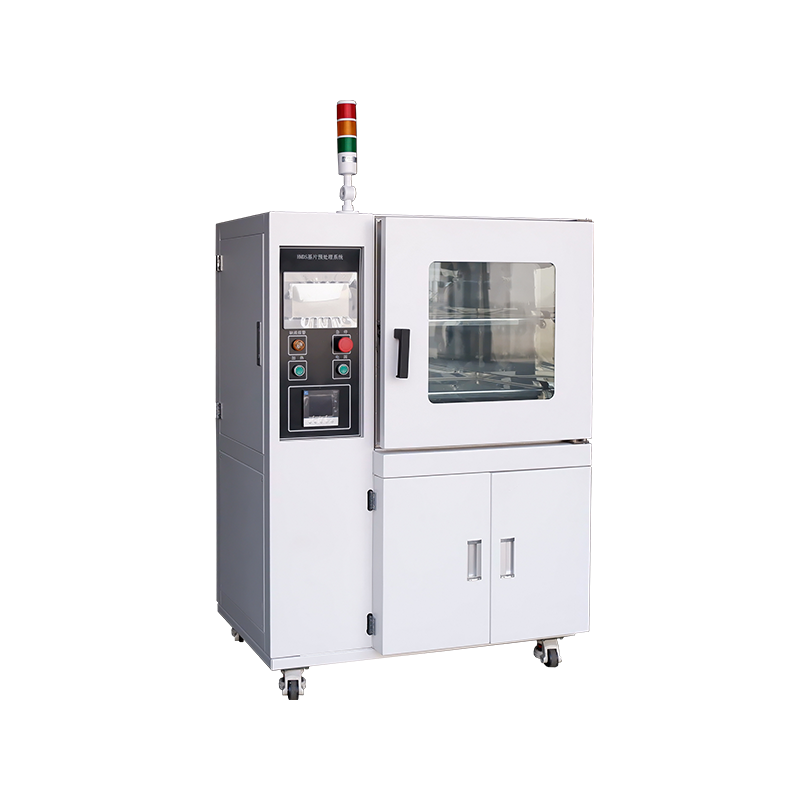

HMDS substrate pretreatment systems are primarily suitable for materials such as silicon wafers, gallium arsenide, ceramics, stainless steel, lithium niobate, glass, sapphire, and wafers. They are specialized equipment for improving the surface activity of substrates before photoresist coating, increasing the adhesion between the photoresist and the substrate. They can also be used for cleaning in other wafer processes, and their application is particularly widespread in chip R&D and manufacturing.

The control system utilizes a PLC industrial automation system with a 7-inch touchscreen human-machine interface, enabling programmed operation, improving processing consistency and reliability, and offering convenient operation and intuitive readings.

Multi-system, multi-functional integration: Integrates vacuum, heating, nitrogen filling, and liquid addition modules, supporting hot nitrogen heating, multiple pre-vacuuming, and purging processes to ensure drying and film formation effects.

Strong environmental compatibility: Supports a wide temperature range of 20~200℃, with a cyclic vacuum degree of 100%. Pa, adaptable to different process requirements;

Extra-large observation window, full-process visualization operation, equipped with a double-layer extra-large observation window (double-layer tempered glass), real-time monitoring of the processing process, reducing the risk of misoperation;

Dehydration baking and adhesion (hydrophobic) treatment are completed in one machine, without transfer, effectively avoiding the danger of HMDS (hexamethyldisilazane C6H19NSi2) leakage;

Automated processing reduces chemical consumption by 80% compared to manual coating, has high repeatability and is harmless to the human body, supports mass production, and reduces costs;

The inner tank is made of corrosion-resistant and acid-alkali-resistant stainless steel (316L type), with rounded corners for easy cleaning; the outer shell is made of high-quality cold-rolled steel plate, with zero surface treatment, electrostatic powder coating, anti-static, dust-free, suitable for chip packaging cleanrooms;

More uniform processing, because it is coated onto the substrate surface in the form of steam, it is more uniform than liquid coating;

Saves chemical solution, coating onto the wafer surface in the form of steam, it can process up to 4 to 20 boxes of wafers at a time, further saving chemical solution; More environmentally friendly and safer: HMDS is a toxic chemical that can cause nausea, vomiting, abdominal pain, chest irritation, and respiratory tract irritation if inhaled. Because the entire process is completed in a closed environment, people do not come into contact with the liquid or its vapors, making it safer. Its exhaust gas is directly pumped into a dedicated exhaust gas collection pipeline or treated professionally, reducing environmental pollution.

| Model | DS-HMDS-50 | DS-HMDS-90 | DS-HMDS-150 | DS-HMDS-210 | DS-HMDS-250 |

| Navar | PLC Industrial PC | ||||

| Human-computer interaction | 7-inch touch screen | ||||

| Temperature range | RT+10~200℃ | ||||

| Resolution / volatility | 0.1℃/≤±0.5℃ | ||||

| Time range | 1~9999min | ||||

| Vacuum/coating/baking | voluntarily | ||||

| Vacuum degree | 99 programming control | ||||

| Accessible vacuum | ≤100pa | ||||

| Smart Security | Power-on self-check, power-off memory, overheating alarm and heating stop, sensor deviation correction, screen lock, three-level permissions | ||||

| Vacuum pump | 2XZ-2B | 2XZ-4B | |||

| Inner liner size | 410x370x345 | 450x450x450 | 500x500x600 | 560x640x600 | 600x600x700 |

| Outline dimension | 820x550x1285 | 860x630x1470 | 670x650x1630 | 980x820x1750 | 1000x800x1850 |

| Volume | 52L | 91L | 150L | 215L | 252L |

| Supply voltage | AC220V/50Hz | ||||

| Power | 1.6KW | 2.4KW | 3.2 | 4KW | 4.55KW |

| Work environment | 0~45℃ | ||||

1. Over-temperature alarm

2. Fault alarm

3. Self-diagnosis upon startup

4. Internal parameter correction

5. Leakage current protector

Products provided by famous enterprises are deeply trusted by users.

Shanghai Dengsheng Instrument Manufacturing Co., Ltd. is a high-tech enterprise integrating R&D, production, sales, and service. We specialize in the manufacture of high-end laboratory equipment, including ovens, incubators, industrial furnaces, and environmental test chambers.

We boast an 8,000-square-meter modern production facility, a dedicated R&D team, 23 national patents, and ISO-9001 quality management system certification. Our solutions are widely used in cutting-edge fields such as aerospace, semiconductors, biomedicine, automotive, and new materials. We have established in-depth partnerships with top universities and industry leaders, and our products are exported to many countries and regions around the world.

Adhering to the principles of "Integrity, Innovation, and Win-Win," we are committed to becoming your trusted partner with reliable quality and dedicated service.

2025/11/27

2025/11/27

2025/11/12

2025/11/12

2025/11/12

2025/11/12