2025/11/27

2025/11/27

With a deep commitment to the global market, Shanghai Dengsheng Instruments has earned international acclaim for its quality.

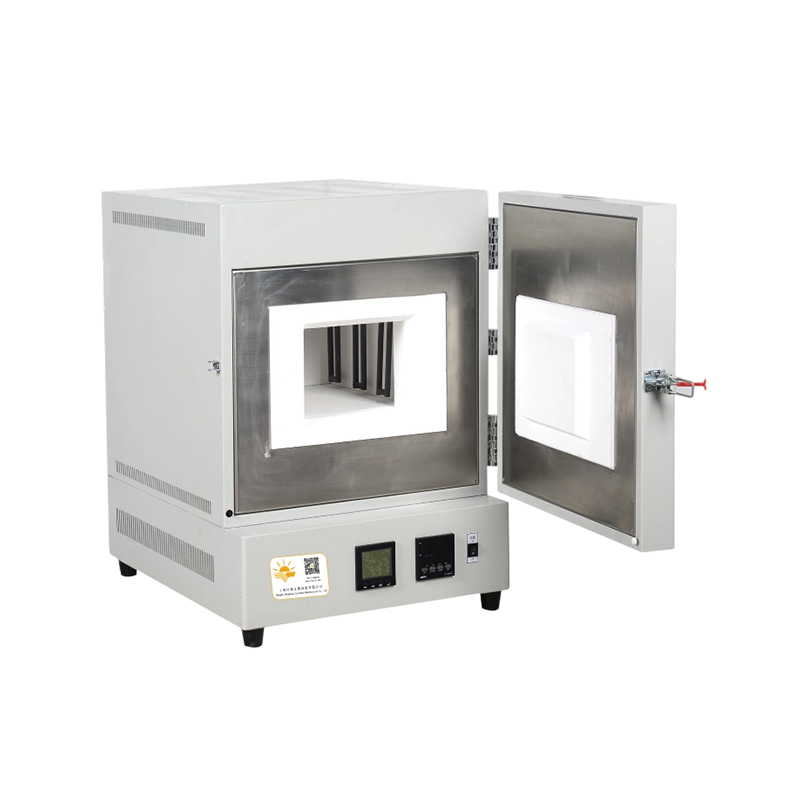

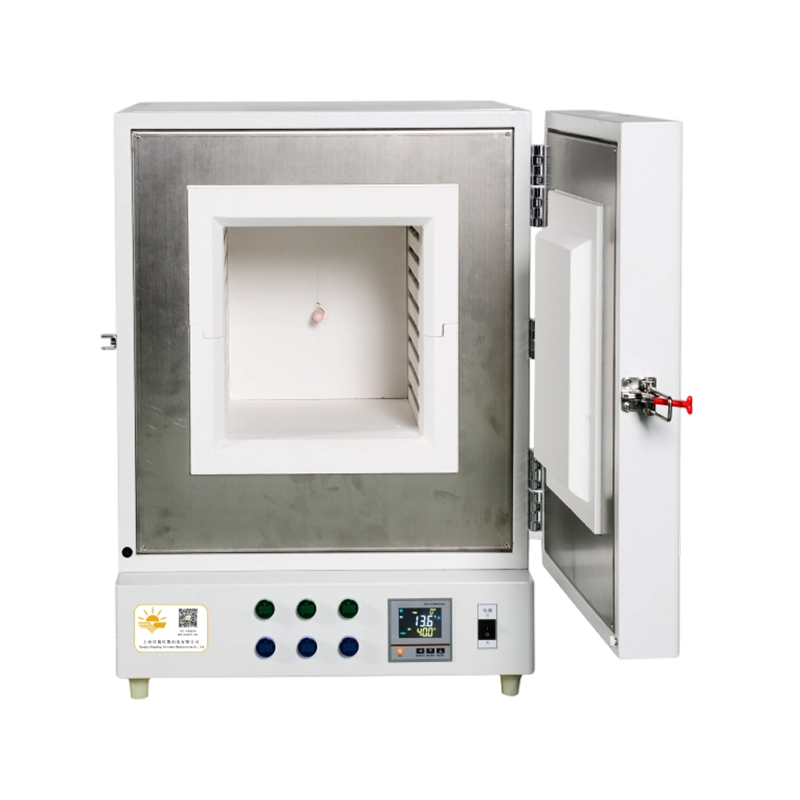

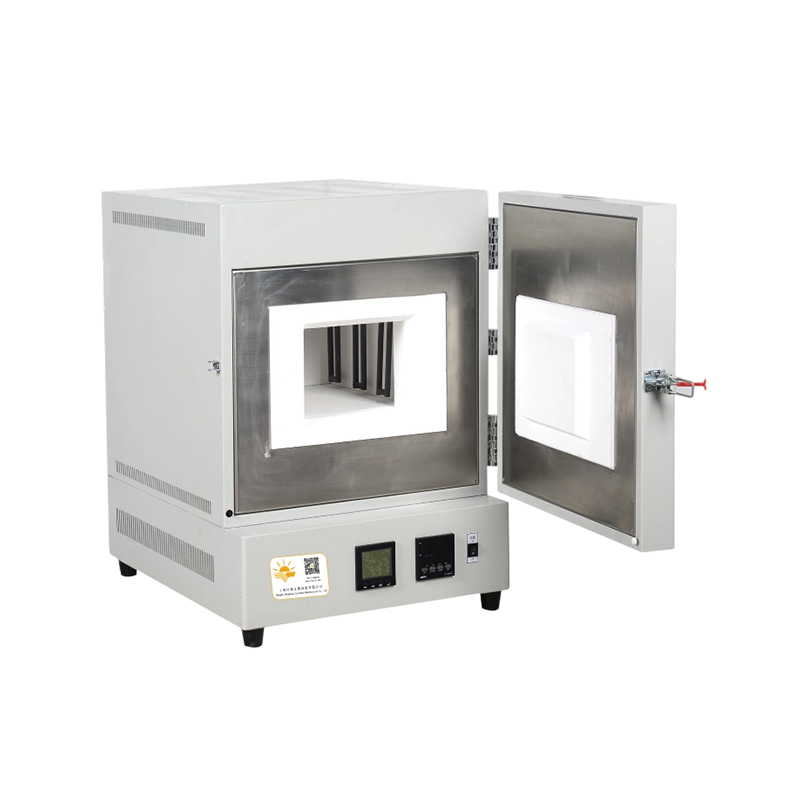

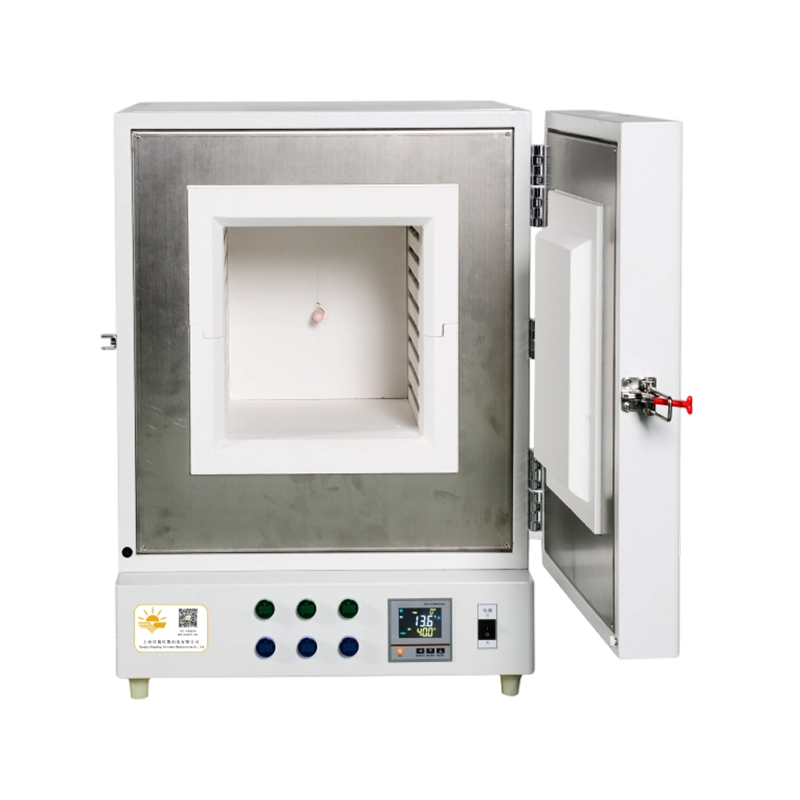

Ceramic fibre muffle furnaces serve as indispensable auxiliary heating equipment for dry sample preparation in analytical laboratories, for melting experiments in materials and metallurgical laboratories, and for processes such as annealing, quenching, sintering, calcination, roasting, melting, ashing, and ash determination in heat treatment departments, as well as other applications requiring elevated temperatures.

1. Integrated all-in-one design with compact footprint, featuring a large LCD controller for intuitive operation;

2. Microprocessor-based intelligent temperature control system with PID logic and automatic parameter tuning for precise, reliable regulation;

3. Automatic parameter retention during emergencies with power-restoration capability, alongside sensor self-diagnosis, leakage protection, over-temperature alerts, and fault alarms;

4. Unique furnace door design where the door tongue partially embeds within the chamber upon closure, preventing high-temperature air leakage. This minimises heat loss for significant energy savings while enhancing temperature uniformity within the furnace;

5. The outer casing employs premium cold-rolled steel plate, CNC precision-engineered with phosphated surface treatment and electrostatic powder coating. This provides corrosion resistance, anti-static properties, and a durable, colourfast finish;

6. The furnace chamber utilises novel ceramic fibre insulation material (polycrystalline alumina fibre, AL₂O₃), offering advantages including light weight, high-temperature resistance, low thermal conductivity, low specific heat capacity, and resistance to mechanical vibration;

7. The furnace chamber employs a modular design. Heating elements below 1200°C are semi-embedded, while those above 1200°C are directly exposed. The insulation material, also polycrystalline alumina fibre, achieves over 97% thermal efficiency, delivering significant energy savings;

8. Premium imported nickel-containing HRE alloy heating wires (1000/1200°C) and silicon carbide rods (1300°C) ensure rapid heating, oxidation resistance, and a service life 3-5 times longer than standard heating elements, delivering more uniform heating;

9. Unique air insulation layer design employs branded circulating fans to force airflow circulation within the insulation layer, substantially reducing the surface temperature of the chamber for safe and reliable operation;

10. Optional 30-segment programmable controller enables stepwise heating with configurable dwell times at each temperature stage, facilitating multi-condition operation (optional);

Muffle furnace (1000/1200°C)

| Model | DTH-2.5A-2 | DTI-4A-7.2 | DT-4A-12 | DTI-6A-18 | DTH-10A-30 | DTI-10A-36 | DTI-16A-80 |

| DTH-2.5B-2 | DTI-4B-7.2 | DTI-4B-12 | DTI-6B-18 | DTI-10B-30 | DTI-10B-36 | DTI-16B-80 | |

| Controller | 4.3-inch triple-row digital LCD display (set temperature, operating temperature, constant temperature duration) | ||||||

| Temperature Control Method | PID intelligent logic calculation | ||||||

| Temperature Range | Type A: RT+50~1000°C Type B: RT+50~1200°C | ||||||

| Temperature Accuracy | ±1°C | ||||||

| Temperature Resolution | 1°C | ||||||

| Heating Time | 1000°C≤30 minutes | ||||||

| Heating Material | HRE alloy | ||||||

| Furnace Chamber Material | Aluminosilicate (ceramic fibre) vacuum-formed monolithic structure | ||||||

| Thermocouple | Type K nickel-silicon thermocouple | ||||||

| Insulation Material | Ceramic fibre board | ||||||

| Housing Material | Powder-coated cold-rolled steel plate | ||||||

| Safety Protection | Overtemperature alarm, door-opening power cut-off, earth leakage protection, rapid fuse, earth leakage protection | ||||||

| Furnace Chamber Dimensions (mm) | 120π200x80 | 200x300x120 | 200x300x200 | 250z400x180 | 300x500x200 | 300x400x300 | 400π500x400 |

| Overall Dimensions (mm) | 430z605x550 | 510π705x590 | 530x715x690 | 570x800x700 | 640x880x730 | 700x860x860 | 800x960z960 |

| Volume | 1.9L | 7.2L | 12L | 18L | 30L | 36L | 80L |

| Gross/Net Weight (kg) | 62/50 | 84/71 | 98/83 | 107/91 | 125/105 | 137/112 | 199/169 |

| Power Supply Voltage | AC220v/15A | AC220v/25A | AC380v/25A | AC380v/30A | AC380v/50A | ||

| Power Rating | 2.5kw | 4kw | 4kw | 6kw | 10kw | 10KW | 16EW |

Muffle furnace (1300/1400°C)

| Model | DTM-4C-3.8 | DTM-6C-6.8 | DTM-8C-18 | DTM-12C-36 | DTM-20C-80 |

| DTM-4K-3.8 | DTM 6K-6.8 | DTM 8K-18 | DTM-12K-36 | DTM-20K-80 | |

| Temperature Control Method | 4.3-inch triple-row digital LCD display (set temperature, operating temperature, constant temperature duration) | ||||

| Temperature Range | Type C: RT+50~1300℃ Type K: RT+50~1400℃ | ||||

| Temperature Control Accuracy | 1℃ | ||||

| Display | High-brightness LCD digital display | ||||

| Sensor | Type S platinum-rhodium thermocouple | ||||

| Heating Element | Silicon carbide heating rods | ||||

| Chamber Material | Aluminosilicate (ceramic fibre) vacuum-formed monolithic structure | ||||

| Heat-Up Time | RT~1200℃≤40min | ||||

| Operating Mode | Constant-value timed operation | ||||

| Timer Range | 1~9999min | ||||

| Safety Protection | Overtemperature alarm, door-opening power cut-off, earth leakage protection, rapid fuse-blow, leakage protection | ||||

| Power Supply Voltage | AC220V/25A | AC3B0V/18A | AC380V/25A | AC380V/35A | AC380V/60A |

| Chamber Dimensions (mm) | 150x250x100 | 150x300x150 | 250x400x180 | 300x400x300 | 400x500x400 |

| Overall Dimensions (mm) | 500x630x660 | 500x680x710 | 610x670x675 | 650x780x850 | 760x900x980 |

| Volume | 3.75L | 6.75L | 18L | 36L | 80L |

| Gross/Net Weight (kg) | 85/70 | 93/78 | 124/108 | 144/124 | 275/245 |

| Rated Power | 4KW | 6KY | 10KW | 18KW | 20KW |

Muffle furnace (1600/1700°C)

| Model | DTM-2.5S-1 | DTM-4S-4.5 | DTM-5S-5.4 | DTM-9S-9 | DTM-12S-12 | DTM-18S-36 |

| DTM-2.5X-1 | DTH-4X-4.5 | DTM-5X-5.4 | DTM-9X-9 | DTM-12X-12 | DTM-18K-36 | |

| Controller | LED High-Brightness Digital Display (Yudian) | |||||

| Temperature Control Method | Microprocessor-Controlled Intelligent PID Calculation | |||||

| Temperature Range | Type S: RT+50~1600℃ Type: RT+50~1700℃ | |||||

| Temperature Control Accuracy | 1℃ | |||||

| Cycling Method | Natural Convection | |||||

| Heating Material | Silicon Molybdenum Rod | |||||

| Furnace Chamber Material | Aluminosilicate (ceramic fibre) vacuum-formed in a single moulding | |||||

| Thermocouple | Type B thermocouple | |||||

| Temperature Rise Time | RT~1500℃≤70min | |||||

| Operating Mode | Fixed-value timed operation | |||||

| Timing Range | 1~9999min | |||||

| Safety Protection | Overtemperature alarm, door-opening power cut-off, earth leakage protection, rapid fuse-blow, leakage protection | |||||

| Power Supply Voltage | AC220V/50Hz | AC220V/20A | AC380V/25A | AC380V/25A | AC380V/35A | AC380V/50A |

| Furnace Chamber Dimensions (mm) | 100*100*100 | 150x200x150 | 150x300x120 | 200x300x150 | 200x300x200 | 300z400x300 |

| Overall Dimensions (m) | 460z600x750 | 510x700x810 | 500x680x680 | 560x570x655 | 550x680x760 | 650780x850 |

| Volume | 1L | 4.5L | 5.4L | 9L | 12L | 36L |

| Gross/Net Weight (kg) | 72/62 | 99/87 | 111/94 | 152/136 | 182/162 | 275/250 |

| Rated Power | 2.5KW | 4kw | 5kw | 9KW | 12KW | 18KW |

Muffle furnace (1800°C)

| Model | DTM-4T-4.5 | DTM-12T-12 | DTM-18T-36 |

| Controller | LED High-Brightness Digital Display (Yudian) | ||

| Temperature Control Method | Microprocessor-Controlled Intelligent PID Calculation | ||

| Temperature Range | RT+50 to 1800°C | ||

| Temperature Control Accuracy | 1°C | ||

| Cycle Mode | Natural Convection | ||

| Heating Material | Silicon Molybdenum Heating Rod | ||

| Furnace Chamber Material | Aluminosilicate (Ceramic Fibre) Vacuum-Formed in a Single Process | ||

| Thermocouple | Type B Thermocouple | ||

| Temperature Rise Time | RT~1500℃≤70min | ||

| Operating Mode | Fixed-value Timing/Program Operation (30 segments) | ||

| Timing Range | 1"9999min | ||

| Safety Protection | Overtemperature Alarm, Door-Open Power Cut-off, Earth Fault Protection, Rapid Fuse, Earth Leakage Protection | ||

| Power Supply Voltage | 380V/25A | AC380V/35A | AC380V/55A |

| Furnace Chamber Dimensions (m) | 150x200z150 | 200x300x200 | 300x400x300 |

| Overall Dimensions (m) | 510x700m805 | 550x700m895 | 850x800x1050 |

| Volume | 4.5L | 12L | 36L |

| Gross Weight/Net Weight (EG) | 135/120 | 192/172 | 295/263 |

| Rated Power | 4KW | 12KY | 18KW |

1. GB/T 28849-2012 Laboratory Box-Type Resistance Furnaces (None)

2. GB/T 30839.43-2015 Energy consumption classification for industrial electric heating appliances — Part 43: Box-type resistance furnaces

3. GB/T 10067.44-2014 Basic technical conditions for electric heating appliances — Part 44: Box-type resistance furnaces (None)

4. GB 5959.4-2008 Safety of Electric Heating Equipment — Part 4: Special Requirements for Resistance Heating Equipment

5. GB/T 5576 — Crude Rubber, Compounded Rubber or Vulcanised Rubber of Classes M, N, O, R and U (None).

6. GB/T 9451-1988 Determination of Total Hardened Layer Depth or Effective Hardened Layer Depth of Thin Surfaces of Steel Components

7. GB/T 9451-2005 Determination of Total Hardened Layer Depth or Effective Hardened Layer Depth of Thin Surfaces of Steel Components

8. GB/T 9452-2012 Method for Determining the Effective Heating Zone of Heat Treatment Furnaces

9. GBT 9452-2023 Method for Determining the Effective Heating Zone of Heat Treatment Furnaces

10. GJ 13-1973 General Technical Conditions for Heat-Treated Components

11. JB/T 10174-2000 Quality Inspection Methods for Shot Peening of Steel Components

12. JB/T 10174-2008 Quality Inspection Methods for Shot Peening of Steel Components

13. B/T 10175-2000 Quality Control Requirements for Heat Treatment

1. Over-temperature alarm

2. Power cut-off upon door opening

3. Earth leakage protection

4. Rapid fuse action

5. Earth leakage protection

1. Touchscreen controller

2. USB port

3. Chimney

Products provided by famous enterprises are deeply trusted by users.

Shanghai Dengsheng Instrument Manufacturing Co., Ltd. is a high-tech enterprise integrating R&D, production, sales, and service. We specialize in the manufacture of high-end laboratory equipment, including ovens, incubators, industrial furnaces, and environmental test chambers.

We boast an 8,000-square-meter modern production facility, a dedicated R&D team, 23 national patents, and ISO-9001 quality management system certification. Our solutions are widely used in cutting-edge fields such as aerospace, semiconductors, biomedicine, automotive, and new materials. We have established in-depth partnerships with top universities and industry leaders, and our products are exported to many countries and regions around the world.

Adhering to the principles of "Integrity, Innovation, and Win-Win," we are committed to becoming your trusted partner with reliable quality and dedicated service.

2025/11/27

2025/11/27

2025/11/12

2025/11/12

2025/11/12

2025/11/12